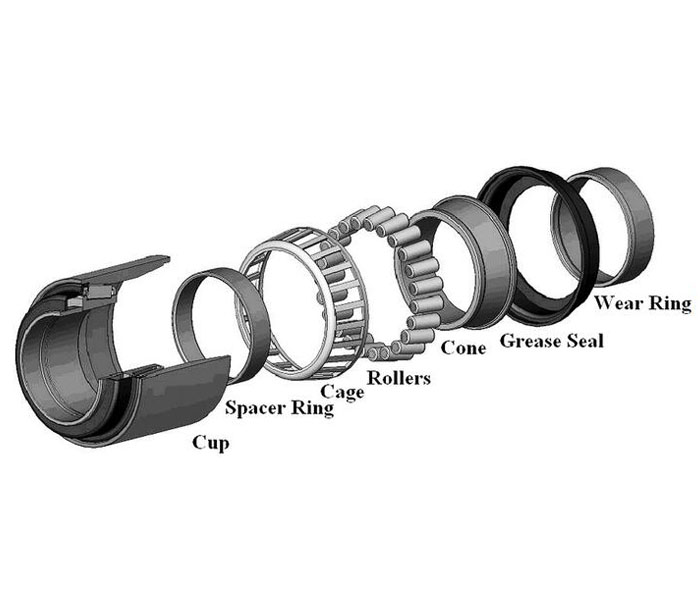

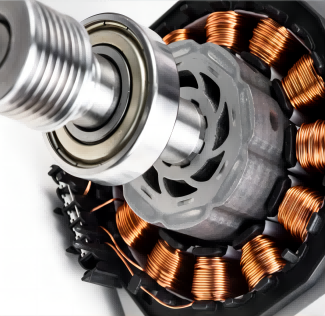

Ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races. There are several common designs of ball bearing, each offering various performance trade-offs. Deep groove ball bearings Angular contact ball bearing Self-aligning ball bearings Axial thrust ball bearings They can be made from many different materials, including stainless steel, chrome steel, and ceramic (silicon nitride, Si3N4). A hybrid ball bearing is a bearing with ceramic balls and metal races.

Read More

| IPv6 network supported |

| IPv6 network supported |